SASB: CG-MR-410a.3

Teams throughout TJX work to implement cost-effective strategies and processes to manage the many different types of waste materials resulting from our operations, such as corrugated cardboard and plastic film. We are doing this in several ways, including by eliminating operational waste where feasible and by taking steps to maximize the reuse and recycling of materials in our stores, distribution centers, and certain corporate offices. These efforts support our global goal of working to divert 85% of operational waste from landfill by 2027.

Our global approach to managing operational waste includes efforts to:

Maximize reuse and recycling of operational waste, of which the majority is corrugated cardboard boxes

Collaborate with our waste-haulers and certain vendors and suppliers on solutions that improve our ability to divert operational waste materials from landfill

Communicate on sortation and recycling procedures within stores

Address single-use plastics in our operations

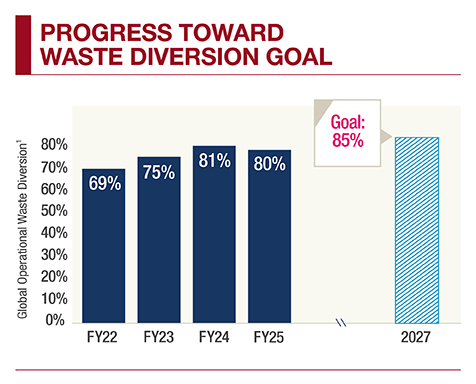

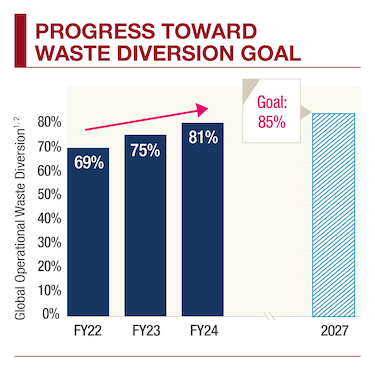

Progress Against Waste Diversion Goal

FY25 Global Operational Waste Diversion Rate:1 80%

Since setting our global operational waste diversion goal in 2022, teams have scaled up their efforts to divert waste and have made significant progress toward meeting our goal. Our operations teams are working hard to achieve our 85% global operational waste diversion rate goal by 2027.

Reuse & Recycling in Our Operations

We have many programs across our global business that support our efforts to reuse and recycle the operational waste in our stores, distribution centers, and certain corporate offices. Recycling programs for common items, like cardboard, plastic, paper, aluminum, and glass, have been introduced in various regions where we operate, and we have been working to find new ways to reduce and recycle difficult-to-recycle items, like polystyrene.

One of our efforts in this area involves backhauling materials from our stores to dedicated facilities to be recycled or reused. In the U.S. and Europe, we have a number of Asset Recovery & Recycling Centers (ARRCs), which are strategically located within our service centers and have historically served as a destination for reusable or recyclable store materials. The majority of our stores in the U.S. and Europe send used corrugated cardboard, plastic film, excess hangers, store fixtures, and other supplies to their local ARRC, or in certain cases, back to a distribution center, where the items are processed and sorted to determine if they can be reused in other stores or recycled.

We continue to focus on initiatives that support reuse and recycling at our stores, ARRCs, and distribution centers, while also exploring ways to further increase our waste diversion.

- Corrugated cardboard comprises the majority of our operational waste, and in recent years we have been focusing on increasing its reuse and recycling in the U.S. and other regions. Thanks to our ARRC network and back-hauling capabilities, a single corrugated cardboard box in the U.S. can be used to deliver merchandise from our distribution centers to our stores up to three times before it is retired and recycled. In Fiscal 2025, over 27 million units of corrugated cardboard packaging were sent back from our stores, through our network of ARRCs, to be returned to distribution centers for reuse. For cardboard that could not be reused, our U.S. Associates helped us recycle more than 115,000 tons of cardboard through our ARRC network in Fiscal 2025. Following successful pilots through Fiscal 2025, we have begun launching larger, more resilient recycling receptacles at all of our U.S. ARRC-serviced stores for holding and transporting recyclable cardboard back to our ARRC locations. We expect that these larger cardboard recycling receptacles should enable us to better leverage the height of the trucks we use to backhaul material back to our ARRCs, thereby helping us recycle more cardboard.

- Over the years, the flexibility of the ARRC program has enabled us to test new initiatives as we strive to increase the amount of difficult-to-recycle material that can be included in our recycling stream. For example, in Fiscal 2024 in the U.S., we piloted a new process for sorting recyclable plastics in our ARRC-serviced stores, with the goal of increasing our ability to recover and recycle plastic film. The test yielded notable improvements in plastic film recovery, and in Fiscal 2025 we expanded the pilot to all ARRC-serviced stores throughout the U.S. As a result of this and other ongoing initiatives, our network of U.S. stores and ARRCs was able to recycle more than 3,300 tons of plastic film in Fiscal 2025—nearly double the amount recycled the year prior. With the help of our partner, some of the plastic film we recycled was used among other materials to make certain receptacle bins that we currently use for collecting plastic film in the back rooms of our stores.

- Our teams are continuously looking for ways to engage our Associates with recycling. For example, in Fiscal 2025 in Canada, the Facilities team initiated an Associate engagement program to help increase rates of plastic film recycling at the stores.

- TJX Europe backhauls plastic film from all of its stores in the U.K., Ireland, and Germany. Stores in the U.K. and Ireland now also backhaul polystyrene. Once these materials are received back at their ARRC or processing center, they are processed for recycling.

Single-Use Plastics

- In certain distribution centers, we have been working to find ways to reduce or replace certain plastics that traditionally protect merchandise as it is shipped to our stores. For example, distribution centers in Canada have replaced the use of bubble wrap pouches with a fiber-based material. In addition to being recyclable, the fiber-based material has reduced merchandise damage and can be reused by stores to protect merchandise carried home by customers. In the U.S., in lieu of plastic bags, we have been utilizing a more easily recycled, corrugated box insert for the packaging of liquid products during shipping to stores.

- TJX Canada has worked directly with certain vendors in a specific merchandise category to utilize a fiber-based alternative for expanded polystyrene (Styrofoam) packaging. The alternative packaging helps protect the merchandise from breakage and is more easily recycled.

- TJX Europe has been working to reduce single-use plastics in offices, processing centers, stores, and e-commerce operations. This has included swapping out plastic tape for paper tape in its e-commerce home deliveries, switching to plastic-free soap sachets and cleaning products in the restrooms and cleaning operations of certain stores and the European home office, and removing single-use plastic refrigerated beverage bottles sold in stores.

- In the U.S., Canada, Europe, and Australia, we have eliminated almost all single-use, petroleum-based plastic food takeout containers in our home office cafeterias and instead utilize predominantly compostable or reusable containers.

Sustainable Sourcing

We continue to work on initiatives related to sourcing certain products, product packaging, and operational supplies with sustainable attributes, primarily focused on areas where we have more control.

Learn moreSustainable Sourcing

We continue to work on initiatives related to sourcing certain products, product packaging, and operational supplies with sustainable attributes, primarily focused on areas where we have more control.

Learn moreWater Consumption

Although TJX’s business operations are not water intensive, we believe managing water usage is consistent with both our commitment to environmental sustainability and our low-cost operating philosophy. To that end, we work to monitor our water usage and identify opportunities to improve water efficiency where feasible across our operations. In certain locations, we also utilize collection systems to use water more effectively; for example, at our processing centers in New South Wales, Australia, and Sulechów, Poland, we harvest rainwater to supply water to the bathrooms and irrigation systems.

In the supply chain, our TJX Vendor Code of Conduct encourages our merchandise vendors to conserve and protect resources, such as water and energy, and to also take into consideration environmental issues that may impact their local communities. Environmental concerns are incorporated into the training materials we provide to merchandise vendors and factory management as well, introducing high-level concepts of environmental sustainability, like water conservation. This training includes specific cost-saving, water conservation recommendations for our suppliers that they may consider implementing at their production facilities.

Spotlight:

Partnerships to Address Waste

TJX has developed partnerships to help give certain items a chance at a second life. For example:

- TJX Canada partners with Pact to offer a beauty product packaging collection program and recently expanded the program to all Winners stores. The Pact program enables customers to drop off used beauty packaging in-store, which is then sent to Pact where it is reused, recycled, or responsibly processed, as feasible.

- Certain Toronto-area stores partner with a local vendor to transform used polystyrene: TJX Canada sends operational polystyrene waste to the vendor, who then turns the waste into frames for things like artwork and mirrors. The framed products have been sold at TJX stores in both Canada and the U.S.

- In Fiscal 2025, many HomeGoods and Homesense stores across the U.S. began partnering with a vendor who collects and processes used wooden pallets. Pallets that meet certain conditions may be salvaged and repaired, sent for reuse, or stripped of nails and other non-wood materials so that clean wood may be ground into mulch, sawdust, or other uses.

1In Fiscal 2025, TJX made revisions to our global operational waste data collection and estimation processes as part of our efforts toward continuous improvement. The revisions included, but were not limited to, the addition of previously excluded stores where TJX does not manage waste operations and estimations to fill gaps in data reported from waste haulers. The revisions are reflected only in our Fiscal 2025 waste diversion rate figure and increased the total volume of our reported waste and recycling.

Updated September 2025